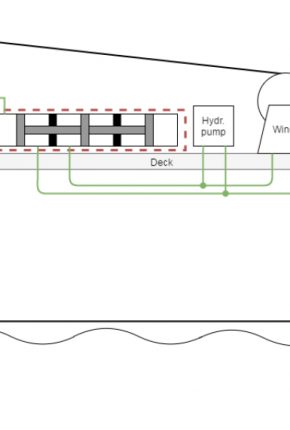

The HeaveCom system extends the area of application for hydraulic heave compensation. Accumulation not only allows the HeaveCom System to make a maximum oil volume available for position correction, it also makes a certain amount of accumulated energy available to execute this correction. Existing heave compensation systems use ‘in-line-cylinders’ with a fixed stroke, which limits the compensation of the maximum heave-induced motion. The active HeaveCom system is designed for the same maximum heave-induced motion that can be compensated for at the given work load. When the effective workloads are lower the HeaveCom system can compensate for higher heave-induced motions, by decreasing the winch motor’s stroke volumes to reach a balance in the nitrogen operating pressure.

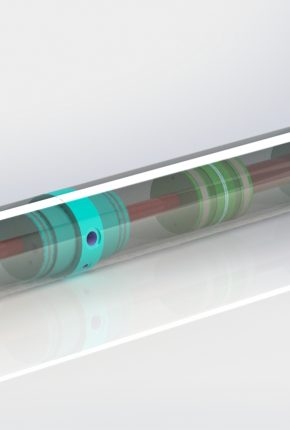

Existing rotating hydraulically driven winch systems are easy to convert to the HeaveCom system. Parallel installation of HYDAC AHC-drive on a winch system provides redundancy to the AHC-system. Direct wear throughout the entire system is reduced, since there is no more need for additional cable disks.

The HeaveCom system saves on energy consumption, mass, nitrogen supplies, reduces wear throughout the entire system and extends the area of application.